Concept

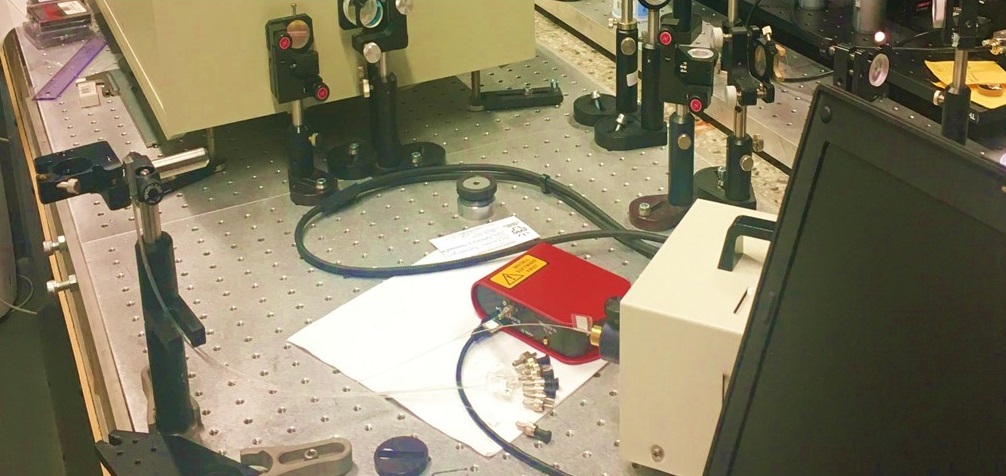

For the final project, I decided to find some ideas related to my research to help my measurements. Then, after discussing with my supervisor, I came up with two ideas. I am working a spectroscopic setup using fiber optics to probe meat samples. But in that setup, there is no focusing and there are no lenses on fibers to focus light on the sample and/or to collect light from the sample. For conducting long-time measurements, focusing is more important since it could provide better signals.

Figure 1. The fiber-optic setup attached to a spectrophotometer in OPEM unit, University of Oulu, Finland.

I will choose the second idea at this stage since it can cover all of the fab academy contents which is required for the final project.

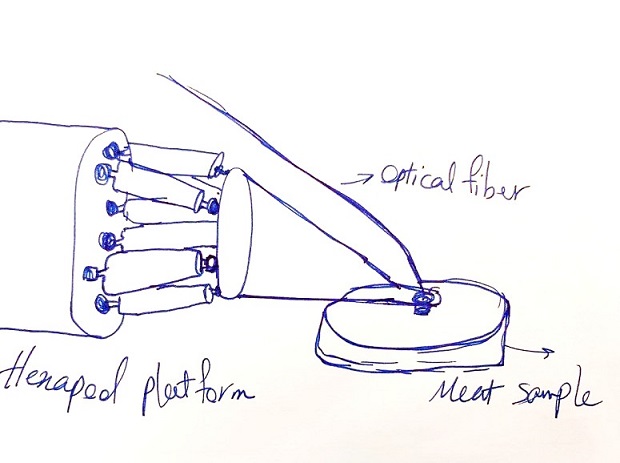

Finally, I came up with the idea of a hexapod platform holding the optical fibers and controlling their movement direction over the sample (Figure 2).

Figure 2. Simple sketch of the hexapod platform attached to an otpical fiber.

After a quick research, I found industrial motorized fiber positioners here.

Figure 3. Industrial motorized fiber positioners.

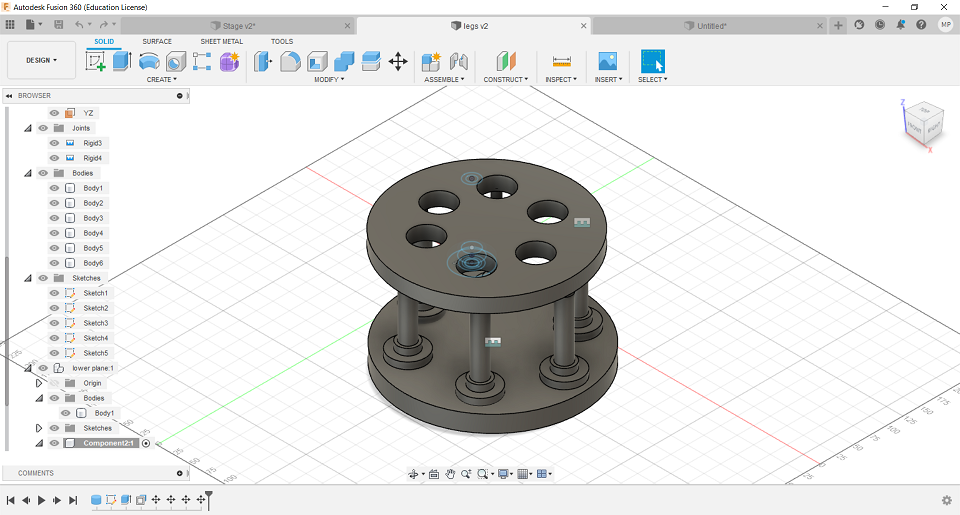

During Week 2 (Computer Aided Design), I started to learn Fusion 360 and as a part of my assignment, I tried to draw a hexapod stage (Figure 3). Week by week and with more practice, I developed the first design.

Figure 4. Basic Hexapod drawing with Fusion 360.

Over Week 3 (Computer-Control Cutting), I learned about kerf concept and parametric design. But since my 3D design were not ready at that time and also I was not sure of the type of material I would use, I could not cut a sample hexapod during that week.

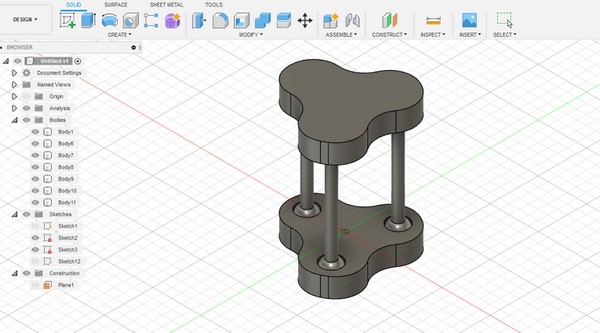

For Week 4 (Electronics Production), I started to make PCB and soldering for my first time. So, I learned the basic skills to make the board for that hexapod stage. But still no idea on PCB programming. After a short discussion with the local instructors, I found that maybe that idea is a bit complicated especially for me with no elctronics. So, I decreased the legs to three for easier programming for control of movements.

During Week 5 (3D Scanning and 3D Printing), I was going to make a threepod stage with moving legs with spherical ends stuck in the upper stage holes but I just finished the 3D design at the time.

Figure 5. Threepod stage with moving legs with spherical ends in Fusion 360.

After Week 6 (Electronics Design) and Week 8 (Embedded Programming), I learned how to program a board with Arduino, but still I was not ready to design and program a board for my final project.

Then, in Week 10 (Embedded Programming), I started to think what kind of input I can consider for my project. Since it would just control the movements of the legs of the stage, it can be a couple of buttons that I had already designed and programmed a board with button during Electronics Design Week. During this week, one of the instructors,Yrjö Louhisalmi, introduced me to Delta robot which is a type of parallel robot that consists of three arms connected to universal joints at the base. The key design feature is the use of parallelograms in the arms, which maintains the orientation of the end effector, by contrast to Stewart platform (which here I found this is how those hexapods with moving stages are called:D) that can change the orientation of its end effector (Wikipedia).

Figure 6. An industrial delta robot (Ref.)

During Week 11 (Molding and Casting), I decided to make the remote control for the project with silicon (although I did something different for that week's assignment).

In Week 12 (Output Devices), I started to think about the type of the output I was going to use in the final project which I will explain more in , so I read a couple of papers to get a bit familiar with Stepper motors and Servo motors which I will explain more in Electronics Design and Production of the final project.